3D Printer Pushbar

Skills:

Solidworks

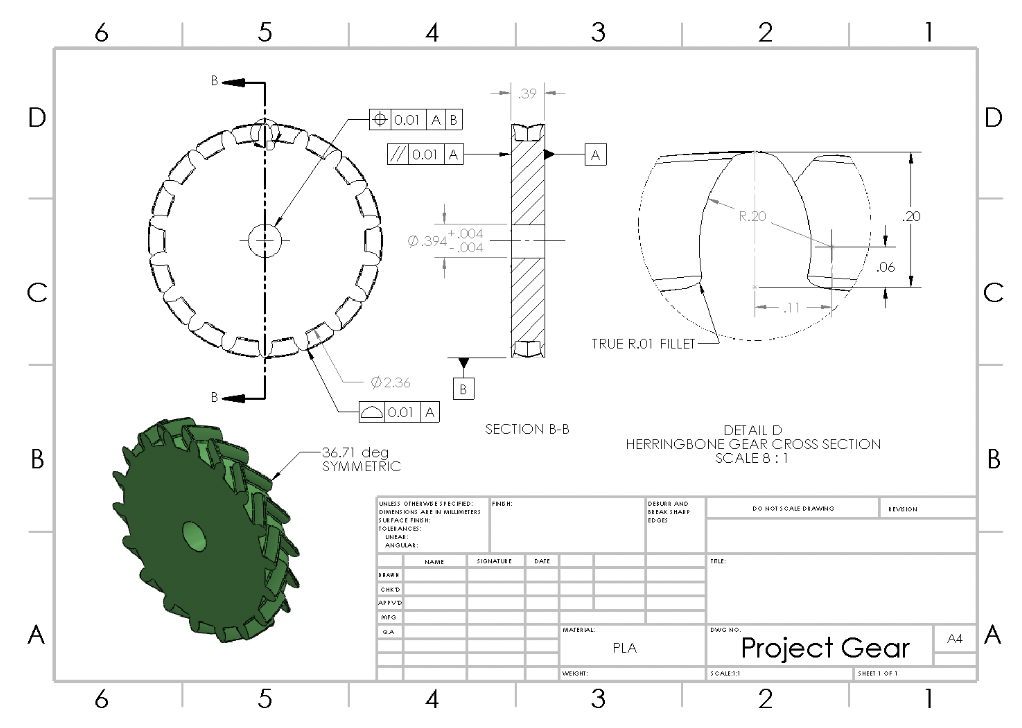

GD&T

Prusa printer full build

GD&T

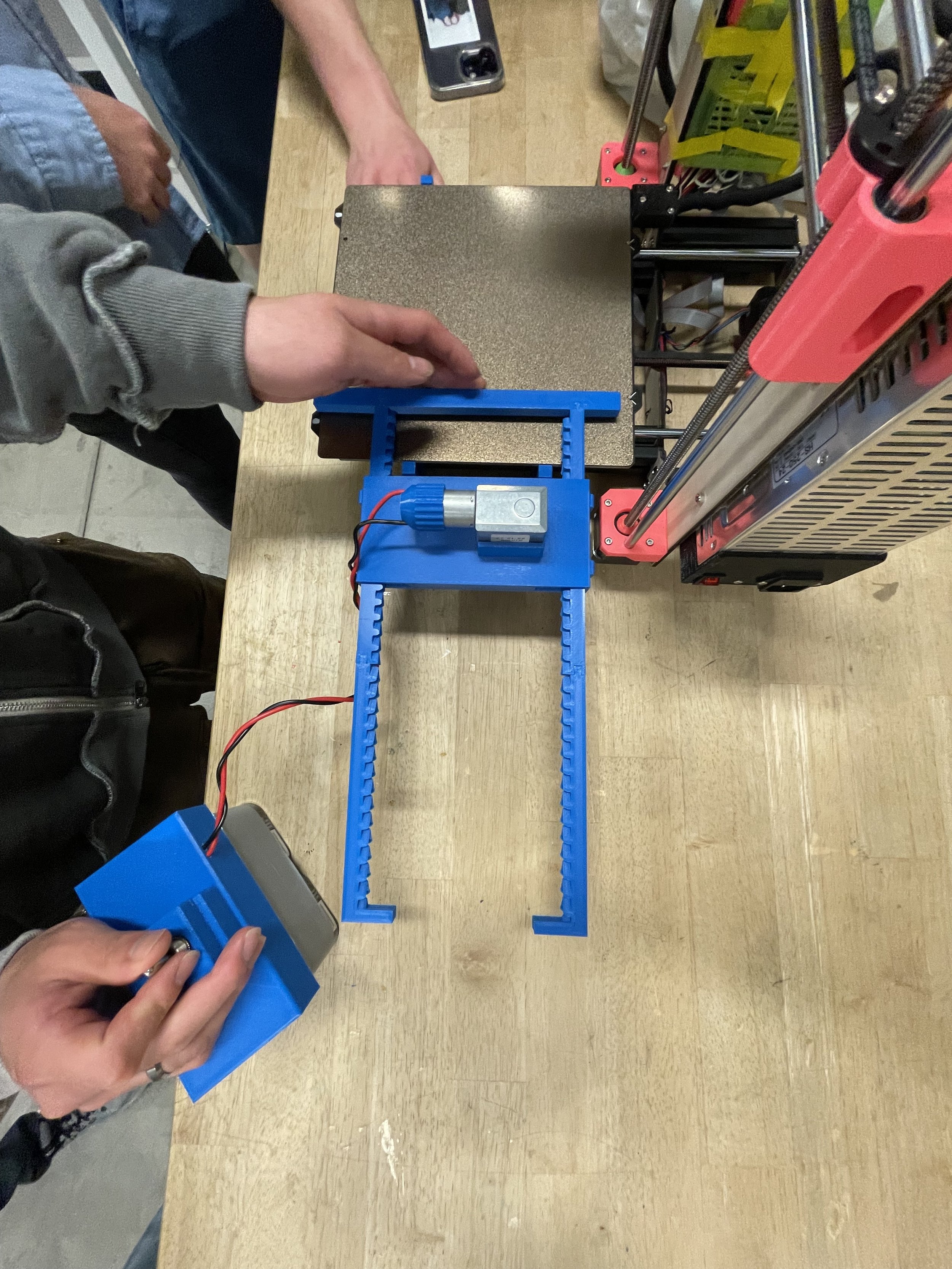

Interference Fit: motor + gear, gears, gear teeth + pinion.

Clearance Fit: gears + gear casing.

Material Selection: PLA

Negligible temperature concern, easy manufacturing for complex herringbone structure, low cost, high strength.

This 3D printer pushbar allows full automation of your print removal process.

Problem Statement: How might we design an additional component to 3D printers to reduce the need of user involvement increase the efficiency of the overall printing process?

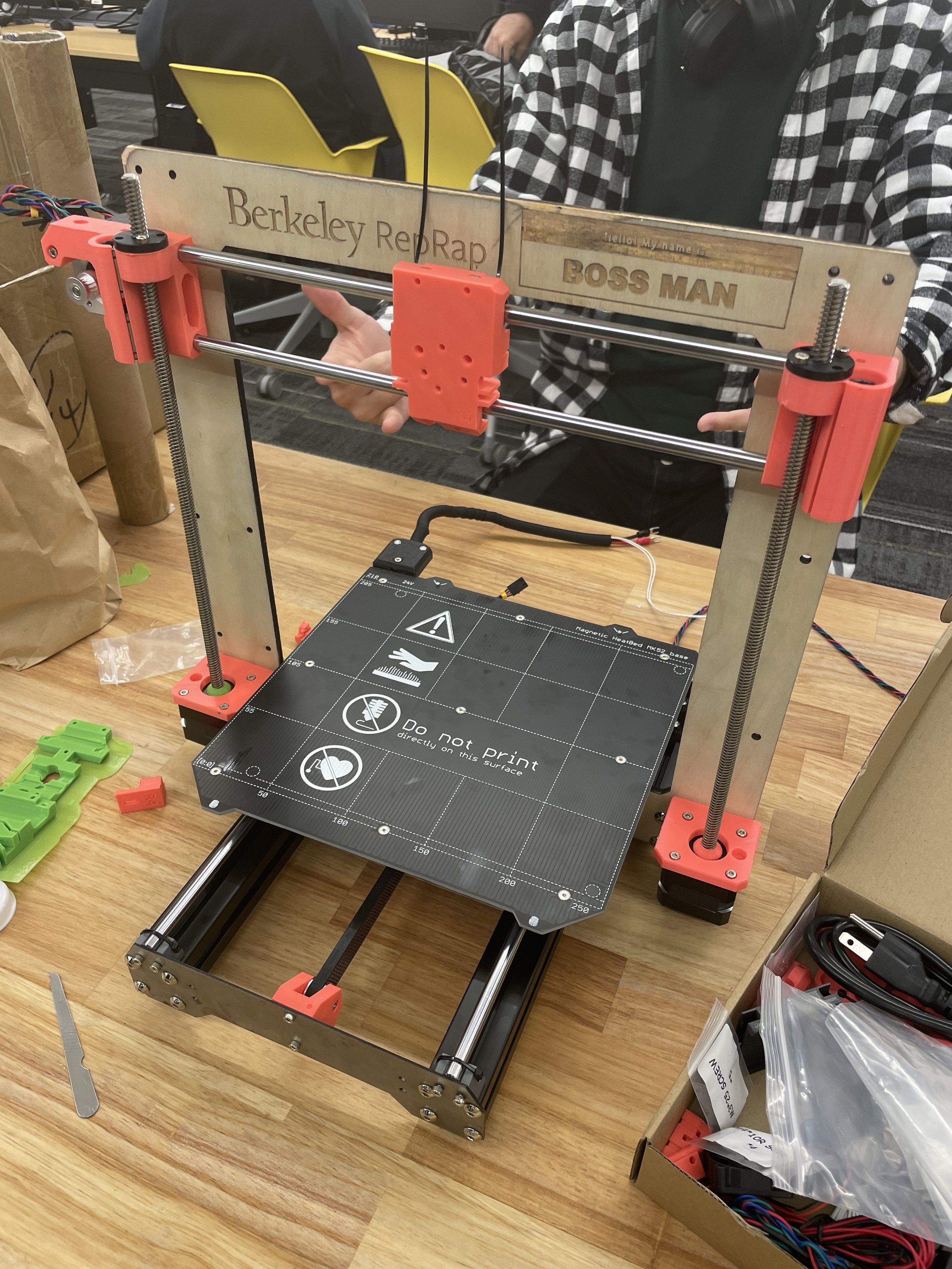

What We Did: Over the course of the semester, our team built a Prusa 3D Printer with a custom designed rack-and-pinion gear operated pushbar. Some requirements for the course project involved dimensioning and tolerancing all parts, and assessing material selection.

Project Demo

Project Demo

Project Demo

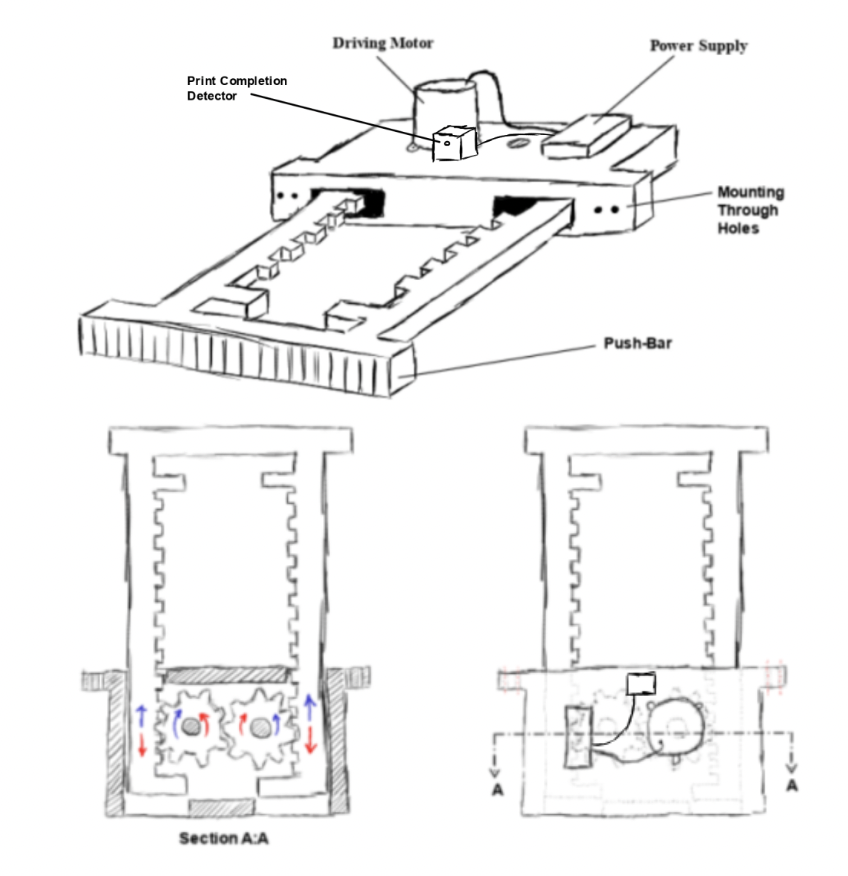

Initial ideation sketch

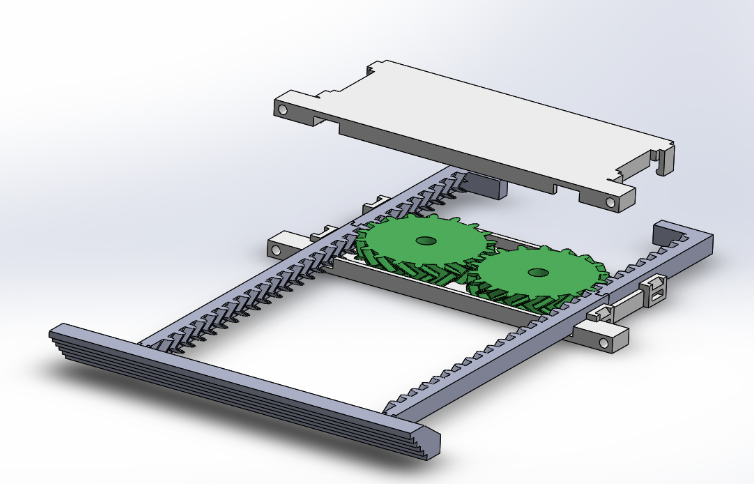

CAD rack and pinion gear

Herring rail rack

Pinion gear

Torque requirements to determine type of motor to buy

12V 3rpm DC Worm Gear Motor

Full CAD assembly

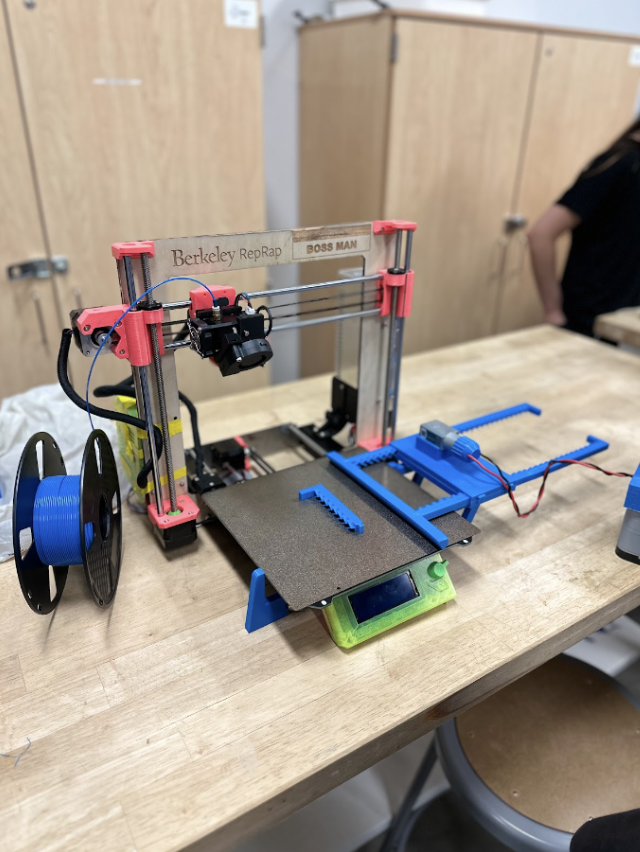

Prusa printer we built throughout semester

Project Demo